company news

How does the medical prototype factory modify the prototype model

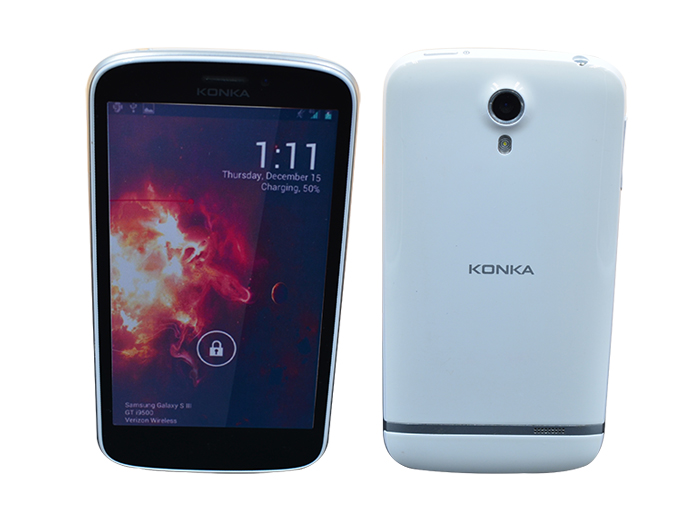

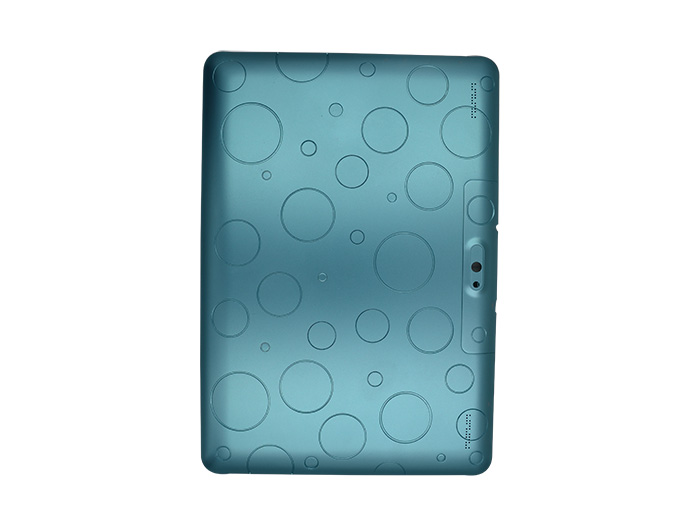

The medical prototype factory is a processing enterprise specializing in the production of prototypes. The main products include all kinds of mobile phones, tablet computers, and digital communication prototypes. The company invests in new production equipment every year, and begins to research and develop new production technologies to improve product quality.

If the medical prototype is colorful or there are colors inside, the color system must be determined. These colors are supplied by resin or pigment, such as adding organic pigments, dyes or powder colorful samples to the matrix resin. The pigment system is also It is necessary to experiment in the final product to ensure that the pigment does not reduce the function of the resin. The proper mixing ratio of the pigment, if possible, the composition should be supplied by the seller. Some organic pigments have a harmful effect on the physical function of the matrix resin in a higher content. It is not significant when it is low. Some plastics may need to be extra clean, and they need to be treated on the surface before retouching to eliminate static electricity. If special treatment and preparation are required, they need to be marked in the sketch and production schedule. Retouching increases the value of the medical prototype model , But if it is not done properly, it will become a defective product, which will reduce profits and cause customer complaints. So how many retouching methods are there for the prototype model?

The retouching of the medical prototype factory can be completed in a variety of ways, such as in-mold retouching, coloring, decals, metal treatment, electroplating, etc. Retouching operations are usually completed in the factory, but more specific operations such as electroplating and metal processing It is done by an outdoor seller. If it is done outdoors, you need to contact the seller to determine the need for surface treatment in the retouching operation. It may include extra cleaning treatment for the board model to satisfy the demand, or Basically, no treatment is required. It is often the case that if the retouching method can cause the medical prototype to break during the retouching process, it is necessary to select specific conditions in order to reduce the molding stress of the product. This kind of appearance is when the plastic is processed by the surface metal. It is often seen that when they need to be etched with acid, if the molding stress in the finished product is too high, it will lead to failure in the manufacture of medical prototypes. These specific questions are asked to ensure the selection of medical prototypes that require retouching Specific conditions. At the same time, the retouching process that affects the data and the prototype model also requires comments, such as cleaning solutions, solvents, etchants, coloring and drying time and temperature, etc. The products to be retouched from the standard production stack are After molding, perform final use inspections as soon as possible to ensure that the molding process does not cause stress on the molded product, which will cause doubts in the retouching process and the final use process.

Tag: medical prototype