common problem

Do you know how to make prototypes?

Prototype models are widely used in industry, so do you know how to make prototypes? The following Shenzhen prototype model will give you a detailed explanation, let's take a look!

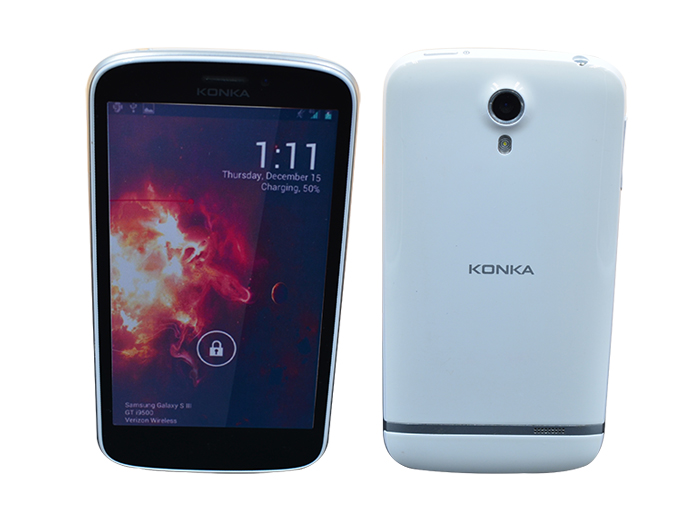

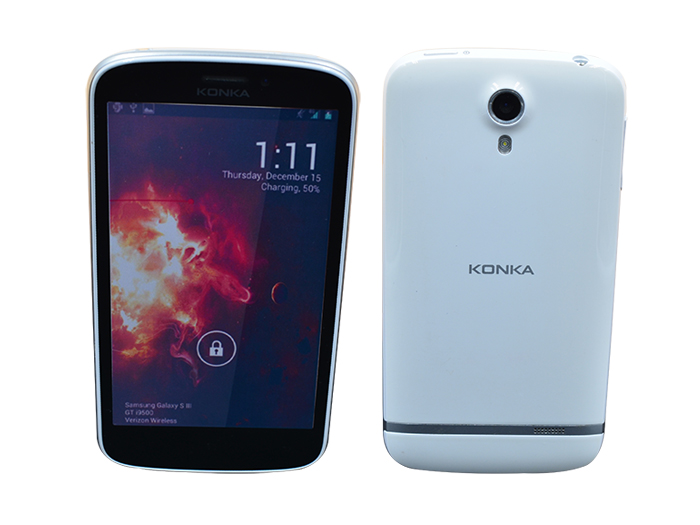

The prototype model is a relatively common type of prototype in the prototype industry. Based on the 16 years of experience in the prototype model, plastic prototypes account for almost 60% of all prototypes. Its production materials mainly include ABS, PC, PMMA, and PU. Species (in addition to POM, PP, PA, etc.). So how is it made? Prototype models mainly include CNC machining, 3D printing and fully automatic vacuum complex mold production methods, and I will introduce them one by one below.

CNC machining

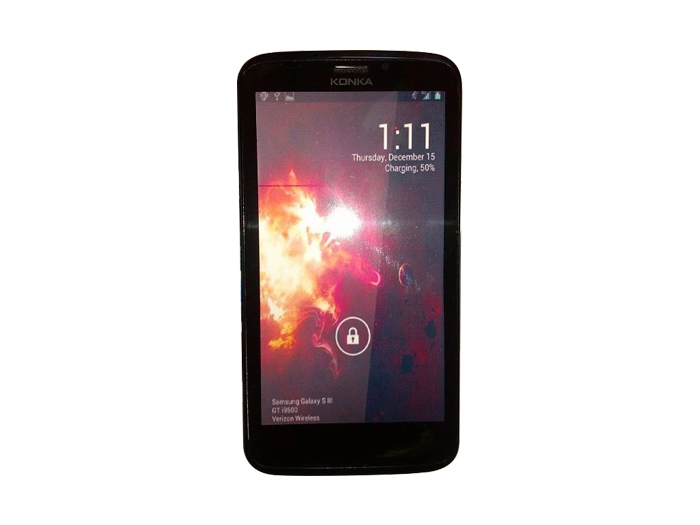

Customers give 3D drawings (if you don’t have 3D drawings, CAD can also be used), and the prototype factory will import your drawings into the computer on a plastic board (may be a thick ABS board or a PP board, depending on your product The material used is selected) for engraving and cutting, that is, carving out the shape of your product on the board, cutting off the unnecessary parts, and leaving the part to form the shape of the product.

CNC machining

3d printing

The ultraviolet light under computer control is gradually scanned and superimposed and cured according to the pre-written program, which is very close to the design drawing file, with high accuracy and fast single room speed. SLA saves labor and is easy to program, but the machine is expensive, the cost is high, and the material is insufficiently brittle and tough. The efficiency of one SLA is equivalent to the efficiency of three CNCs.

Vacuum complex mold

Use the original template to make a silicone mold under vacuum, and then use this silicone mold for batch replication. If the customer requires several sets or dozens of sets, this method is suitable, which greatly reduces the cost. The processing principle of low-pressure perfusion is similar to that of vacuum complex moulding, except that this method processes large prototypes, such as bumper prototypes.

Vacuum complex mold

The above has introduced you to CNC machining, 3D printing, and vacuum complex molding of several plastic parts prototype production methods, I hope to help you.

Tag: Shenzhen prototype model