common problem

What are the requirements for the production of medical device prototypes

A new round of scientific and technological revolution and industrial transformation are gestating and emerging, forming a historical meeting with industrial transformation and upgrading and the transformation of economic development mode. "University of Minnesota professor Pei Youkang said, "The new wave of technological innovation represented by 3D printing, intelligent robots, big data, cloud computing, mobile Internet, etc., is accelerating the transformation of emerging industries. Medical products and medical equipment will no longer cost Customized at a price of one million, only need to make a prototype, the price is much lower than that of customized medical equipment for one million, and it is relatively stable and safe in all aspects!

The following describes the requirements of medical device prototypes:

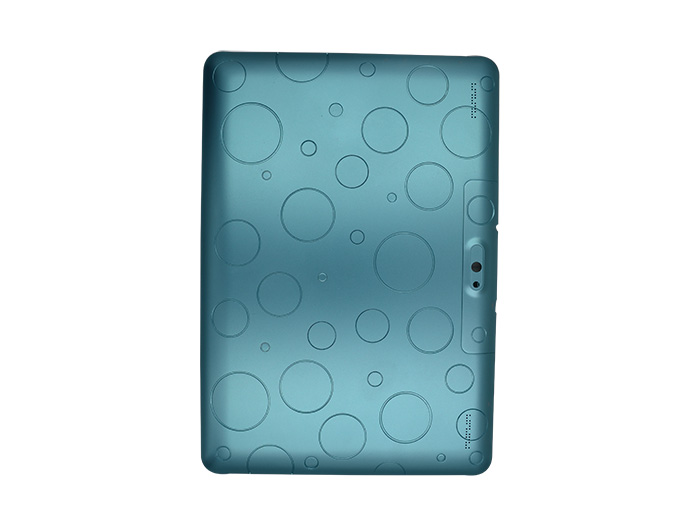

The medical device hand plate is made of stainless steel. We often see the natural case shell, and some people think that the natural case shell is not surface-treated. This is a wrong understanding. The natural color chassis shell can have such a gloss after surface treatment.

There are five coloring methods for medical device prototypes: chemical oxidation coloring, electrochemical oxidation coloring, example deposited oxide coloring, high temperature oxidation coloring, and gas phase understanding coloring. The surface treatment process of the chassis shell not only beautifies the appearance of the chassis cabinet, but also prolongs the service life of the chassis cabinet.

The choice of colors is also very particular. For example, black, white, and gray are called international popular colors. On the one hand, cool colors are good for the device itself, and on the other hand, it also has the effect of isolating radiation for users. As the technology matures, we can keep the paint life of the chassis shell to the maximum. Cool colors can make the operator maintain a clear mind. Cool colors can make the use of internal circuits clearer. With the development of social economy, the sheet metal chassis shell is also developing closely. For the chassis shell, the cool color is the international popular color.

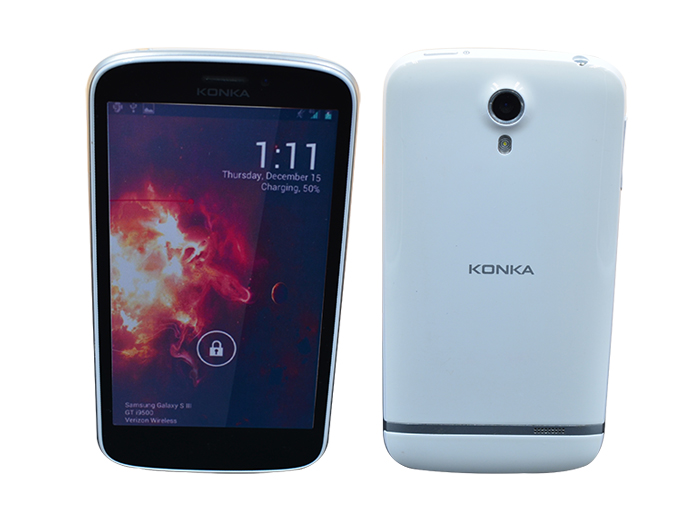

Tai Tengxin specializes in digital communication prototypes, household appliances prototypes, medical equipment prototypes, auto parts prototypes, SLA prototypes, complex prototypes, drones, etc. The prototype is the first step for customers to verify products. , Quality and timeliness need to be driven by both. Constantly develop, keep making progress, sincerely unite and work together. After several years of hard work, Tai Tengxin has gradually developed into a professional prototype processing factory with a certain scale, adhering to the concept of "quality is the life of the enterprise" and "striving for perfection" to serve customers and society, and provide customers with a lot of quality The excellent prototype has won the trust and support of our customers.