common problem

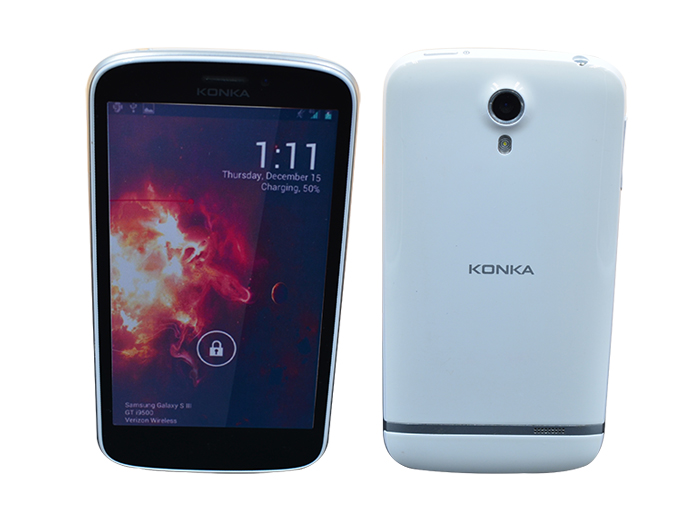

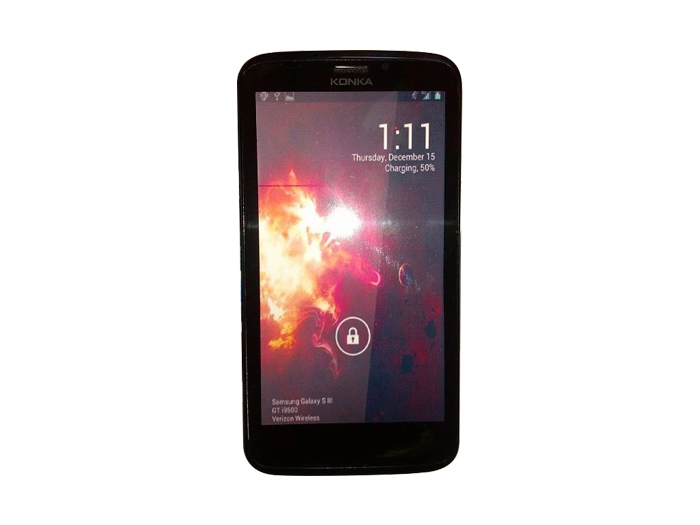

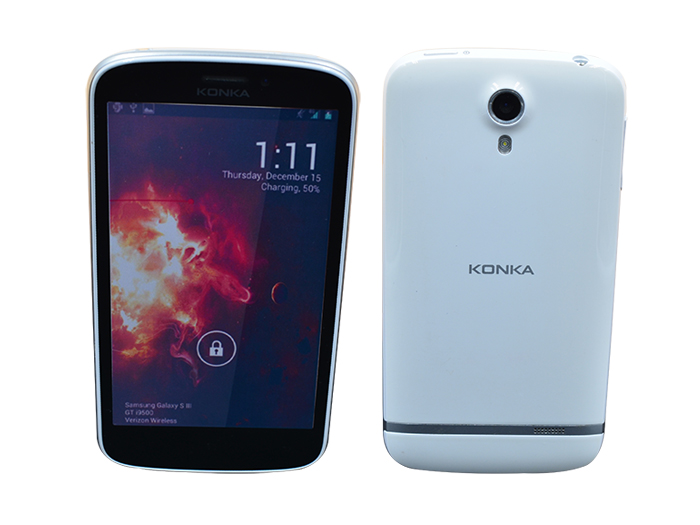

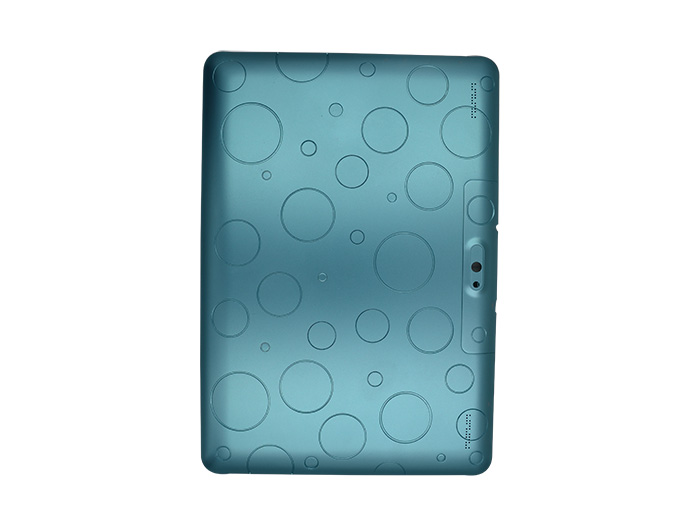

Can the prototype model be electroplated?

Everyone has higher and higher requirements for hand-board models, getting closer and closer to real products, so electroplating surface treatment is often used. Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis, thereby preventing metal oxidation (such as rust) and enhancing aesthetics or conductivity. Many plastic prototypes need to be plated with a layer of metal in order to make their surface look like made of metal. This process is called electroplating.

Plating includes water plating and vacuum plating. In the process of making Tai Tengxin prototypes, the specific method used depends on the characteristics of the prototypes. Some prototypes (such as rings) are small in size and cannot be fixed with fixtures. Hang it up and soak it in the potion. This method is called water plating. Some prototypes of prototypes are relatively large and can be fixed on the fixture, sprayed with conductive paint, and then vacuumed. This method is called vacuum plating. Conventional product prototypes generally use ABS material, which is easy to process, and the post-processing of the prototype is also more beautiful.