Industry News

What is the difference between an injection mold and a prototype model

Prototypes are usually processed on a precision engraving machine with plastic or metal, or in the form of 3D printing or overmolding. Several samples or small batch production are made. The opening of the mold means that the mold is processed first, and then the mold is used for injection molding to mass produce the product. Generally, first confirm to the customer with the hand plate, and then open the mold for mass production.

The prototype is a sample of the product. When your design drawings come out, the designed product is generally not perfect, or even unusable. Once the direct production is defective, it will be scrapped, which greatly wastes manpower, material resources and time; and the prototype production cycle is short. , It consumes less manpower and material resources, and quickly finds out the shortcomings of product design and then improves it, providing sufficient basis for product finalization and mass production.

3D printing: The prototype is made by laser printing and additive processing. The production cycle is very fast. It usually takes only half a day to complete the printing and polishing. Now metal materials such as stainless steel and aluminum alloy can be printed, and the printed prototype surface Rough, but metal printing is very expensive.

CNC processing: CNC processing is processing using CNC equipment such as precision engraving machines. It is the mainstream processing method in the current prototype industry. The processing materials are not particularly limited. Basically, plastic, aluminum alloy sheets, foam, foam, etc. can be realized.

Silicone composite mold: This process is to make an original version first, the original version can be made by CNC processing or 3D printing, and then repair the original version to make a silicone mold. The silicone composite mold can choose ABS, PP, PC, POM , TPU and other materials.

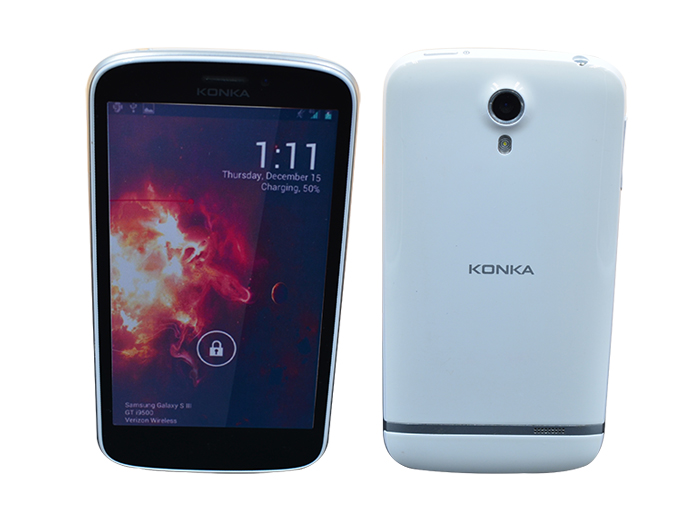

There is little difference between CNC prototype processing and mold processing in terms of processing methods. They both use some CNC processing equipment such as machining centers, precision carvings, and CNC lathes. There is a big difference in terms of the processed material. Prototype processing is mainly processing polymer materials, such as PC, ABS, nylon and other plastics. After taking block materials, carving and milling, polishing and painting, the final product is generally a model developed by the customer. If it is done well, it will follow the future. The products are exactly the same in appearance. The purpose is self-explanatory, it is for the product to have an intuitive confirmation of the product's shape, color, coordination and other related data before mold opening, and to reduce the risk of mold opening.

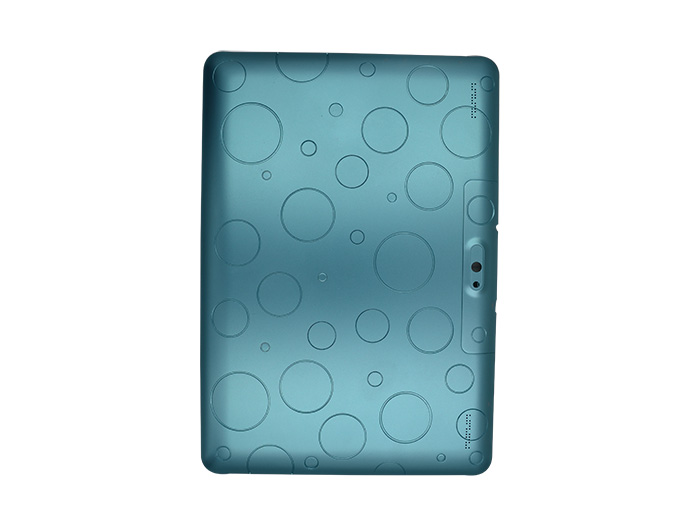

The mold is the metal mold of each plastic or metal part after the hand plate is confirmed. It is a tool that can produce parts with certain shape and dimensional accuracy requirements. Generally steel molds, the requirements for machine tools and tools are much higher than those for processing prototypes, and the processing costs are also much higher. Common in our lives, such as TV sets, telephone shells, plastic barrels, etc., are plastics heated and injected into molds for cooling. Produced.

Although there are so many differences between the prototype and the mold, they are still related. Generally, the prototype is first confirmed to the customer by the prototype, and then the mold is opened for mass production after confirmation. The cost of mold manufacturing is very high, especially the value of large-scale molds such as medical treatment and automobile is hundreds of thousands or even millions. If there is an unreasonable structure or other problems in the process of making the mold, the risk is great. The prototype model can solve this problem well and reduce the risk of mold opening.