Industry News

There are also characteristics and requirements for the production of digital communication prototype molds

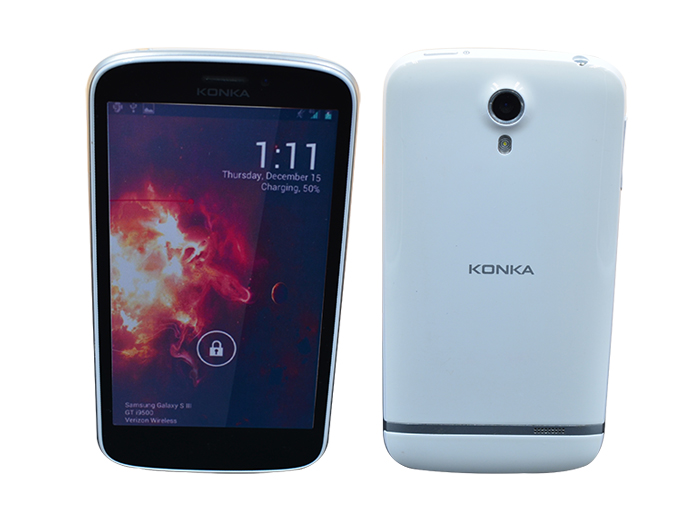

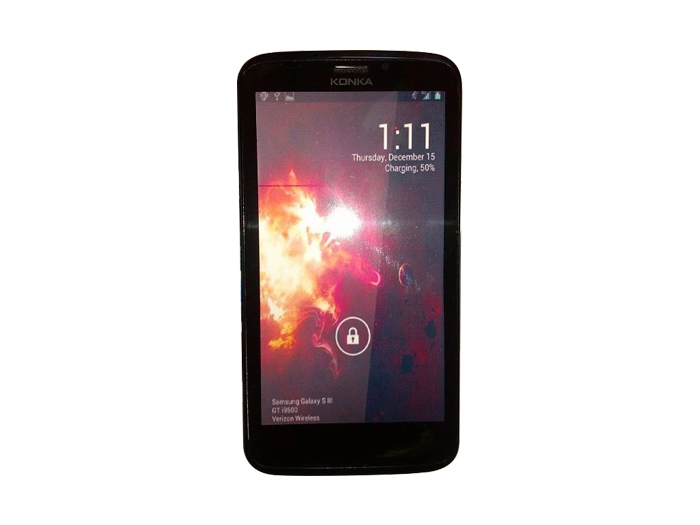

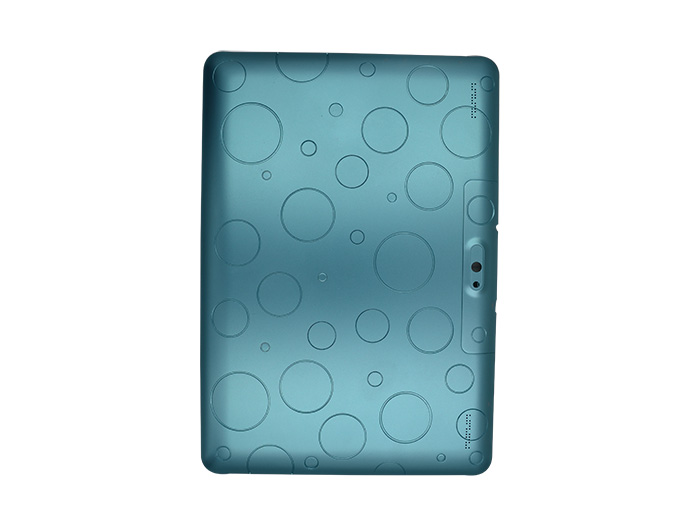

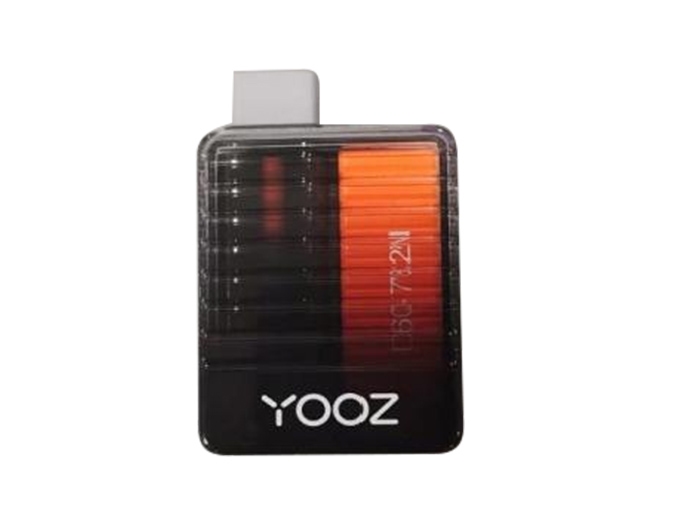

The digital communication prototype manufacturer is a processing enterprise specializing in the production of prototypes. The main products include all kinds of mobile phones, tablets, and digital communication prototypes. The company invests in new production equipment every year, and begins to research and develop new production technologies to improve product quality.

Digital communication prototype manufacturers are not only visible, but also touchable. They can intuitively reflect the designer's creativity in the form of objects, avoiding the disadvantage of "drawing to look good but not making it good". Therefore, the prototype Production is indispensable in the process of new product development and product shape deliberation.

Digital communication prototype manufacturers are assembleable, so it can intuitively reflect whether the structure is reasonable or not, and the difficulty of installation. It is convenient to find and solve problems early.

Avoid the risk of opening the mold directly.

Since the cost of mold manufacturing is generally very high, relatively large molds are worth hundreds of thousands or even millions. If unreasonable structure or other problems are found in the process of opening the mold, the loss can be imagined. Prototype production can be avoided. This loss reduces the risk of mold opening.

Digital communication prototype manufacturers need to modify the product components, or input information during molding, or attach information to the prototype model after molding, all of which need to be fully described, refined and explained in their respective sketches. Because of the prototype production Advanced, you can use the prototype to promote the product before the mold is developed, and even the early sales and production preparations, to occupy the market as soon as possible. If the prototype model is colored or has colors inside, the color system must be determined. These The color is provided by the resin or pigment, such as adding organic pigments, dyes or powder color samples to the matrix resin. The pigment system must also be tested in the final product to ensure that the pigment does not reduce the performance of the resin.

The exact mixing ratio of the digital communication prototype manufacturer, if possible, the ingredients should be provided by the seller. Some organic pigments have a harmful effect on the physical properties of the matrix resin when the content is low. Some plastics may require special cleanliness. Surface treatment is required to eliminate static electricity. If special treatment and preparation are required, it needs to be marked in the sketch and production schedule.

The modification of digital communication prototype manufacturers has increased the value of the prototype model, but if it is not done properly, it will become a defective product, which will reduce profits and cause customer complaints. The modification of the prototype model can be completed in various ways, such as in-mold modification , Coloring, decals, metal treatment, electroplating, etc. The finishing work is usually done in the factory, but more specific work such as electroplating and metal treatment is done by an outdoor vendor. If it is done outdoors, you need to Contact the seller to determine the requirements for surface treatment in the retouching operation. It may include special cleaning treatment for the hand model to meet the needs, or no treatment at all. It is often the case that if in the retouching process Modification methods can cause the prototype model to break, and it is necessary to select specific conditions to reduce the molding stress of the product.

Tag: digital communication prototype