Industry News

Polishing process of complex model hand model company

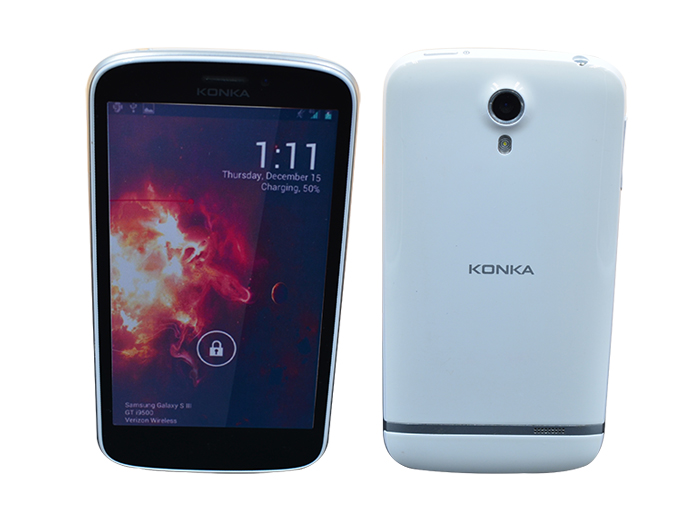

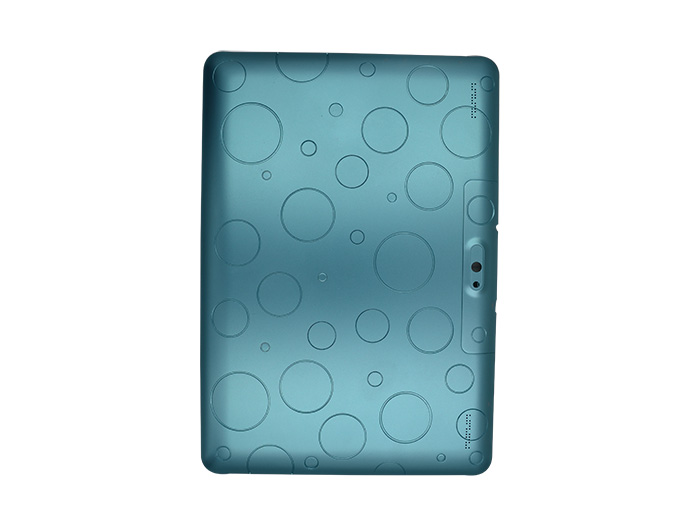

The complex model prototype company is a processing enterprise specializing in the production of prototypes. The main products include all kinds of mobile phones, tablet computers, and digital communication prototypes. The company invests in new production equipment every year, and begins to research and develop new production technologies. improve product quality.

Grinding is basically a technological process that the products of the complex model company must go through. After a part is processed by a CNC machine tool, the surface will have a lot of burrs and knife marks.

The complex model company is divided into the appearance complex model company and the structure complex model company. Here we want to explain to you the color and surface treatment requirements of the appearance complex model company. Products with general appearance require surface treatment As close as possible to the finished product, the appearance effect can be tested. Commonly used in Dongguan complex model prototype company, the appearance processing includes sanding, ash spraying, polishing, coloring, silk screen printing, electroplating flocking, laser engraving and UV highlighting, etc.

These machines are unavoidable. Then you need to manually deal with these defects. Generally, we use sandpaper or polishing paste for polishing. During this period, we can also use some ash spray treatment to test the effect and quality of manual polishing.

When sanding, you first need to use very coarse sandpaper for roughing and sanding. After removing the thick burrs on the surface, you can sand the fine lines. Sandpaper can be divided into 800, 1000, 2000 and other different grades.

The complex mold prototype company must perform different degrees of polishing according to the requirements of the product on the surface! After polishing once, by spraying a layer of putty, the roughness of the product surface can be enlarged. So that it can be seen with the naked eye The degree of flaws. Then you can focus on local corrections, until a product has finally completed the entire polishing process!

Tag: complex model hand model