Industry News

What should be paid attention to when making plastic prototypes?

Prototypes, also called first boards, prototypes, verification parts, prototypes, scale models, etc.! In layman's terms, the product is manufactured in small quantities for verification samples before finalization.

In the industrial design and development of new products, it is necessary to do prototype proofing, because usually 80% of the production cost is determined in the design stage, which is an important part of controlling product costs. In the current product development process of an enterprise, industrial design always plays an important role in the overall situation. The decision at the beginning of industrial design is to consider the entire cycle of product design positioning, cost control, manufacturing, quality inspection, publicity and display, marketing, and recycling, with far-reaching influence. In the industrial design process, model making is an important link. From pure manual model making to semi-mechanized model making to modern CAM, the progress of prototype model making is a microcosm of the progress of modern manufacturing technology. Practice has proved that the production of prototype models is not only right Product design decision-making plays a very important role, and it is a weapon for confidentiality of product information and marketing, which should not be underestimated. Let's take a look at the different stages of the industrial design process: So, what should be paid attention to when making plastic prototypes? I believe everyone is very concerned about this issue.

When making prototypes, you must first have a 3D drawing of the product sample, which is a three-dimensional diagram of the product, because the prototype is made according to the size of the 3D drawing. When sending the 3D drawing file to the prototype manufacturer for processing, Pay attention to the format of the 3D drawing file, because not all drawing file formats can be opened by the prototype factory, so it is best to ask the prototype to open those formats when sending. The most important thing is that the 3D image file sent must be complete, not sloped or incomplete. Because incomplete and sloped drawings cannot be processed and produced.

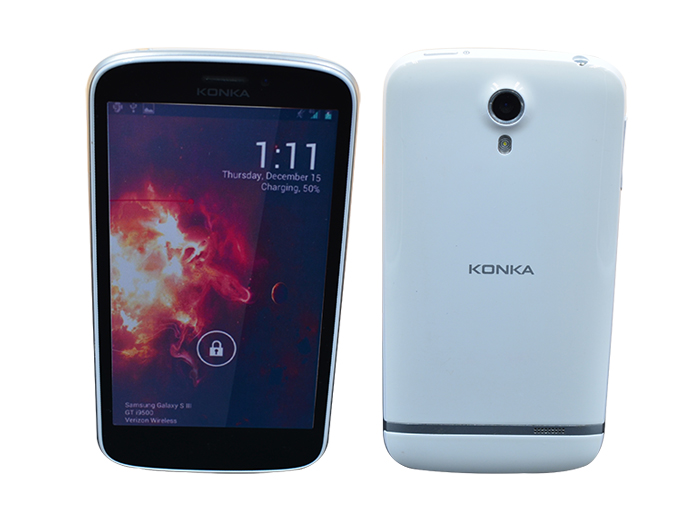

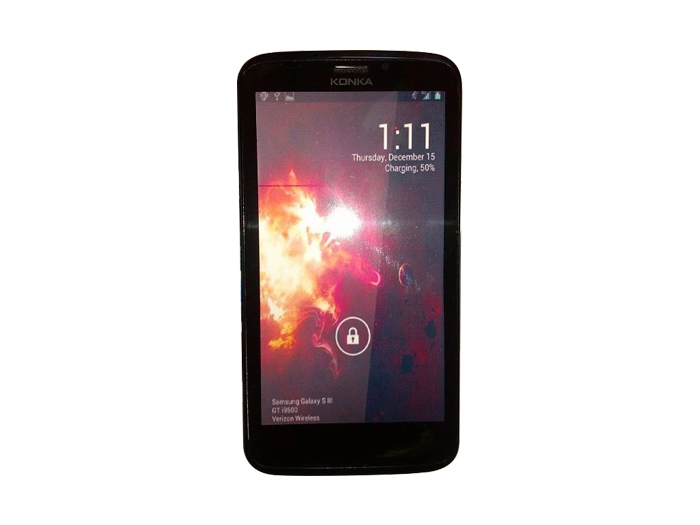

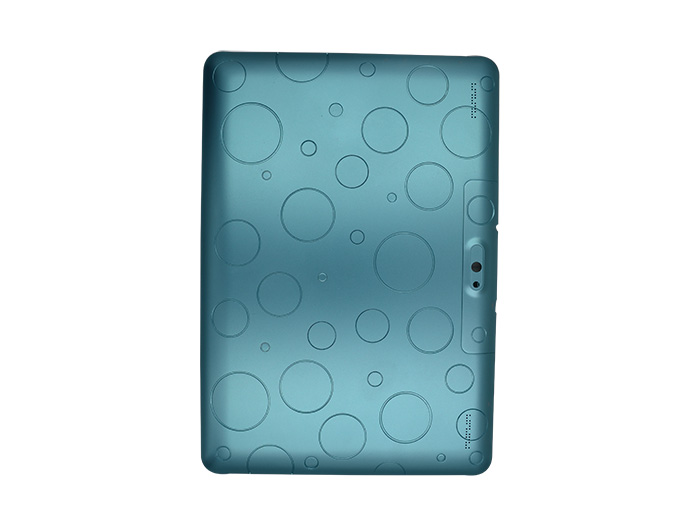

Secondly, when making prototypes, you must explain some details to the prototype manufacturers, such as the choice of prototype materials, whether it is plastic or metal, domestic or imported, and whether to spray, silk screen, electroplating and other surface effects deal with. If you need to, you must tell the prototype manufacturer clearly, especially some details. Otherwise, the prototype will not match your expectations, which will waste time and fail to meet your requirements.

Finally, confidentiality is also very important when making prototypes, because new products are most likely to be known and plagiarized by opponents and peers during proofing. Therefore, when making prototypes, it is best to choose a manufacturer that can independently complete the prototype production. At the same time, you must sign a confidentiality agreement with the prototype manufacturer to establish a long-term cooperative relationship, so that 3D drawings will not be known to more people, and your intellectual property rights can be better protected.